The journey of a custom part doesn’t end when the CNC machine makes its final cut. The raw, as-machined part is often just the starting point. The surface finish—a secondary process applied after machining—is a critical step that defines a part’s final look, feel, and performance.

Choosing the right finish is essential. It can enhance corrosion resistance, improve surface hardness, provide electrical insulation, and deliver the exact aesthetic your project demands. However, with dozens of options available, making the right choice can be challenging.

This guide provides a practical overview of the most common surface finishes for CNC machined metal parts, helping you understand the options and select the best one for your application.

What You’ll Find in This Guide

- As-Machined Finish

- Bead Blasting

- Anodizing (Type II & Type III)

- Powder Coating

- Polishing

- Passivation

- How to Choose the Right Finish (Comparison Chart)

Have a part that needs a specific finish?

At JFManufacturer, we offer a wide range of finishing options. Upload your design to get an instant quote and explore the possibilities.

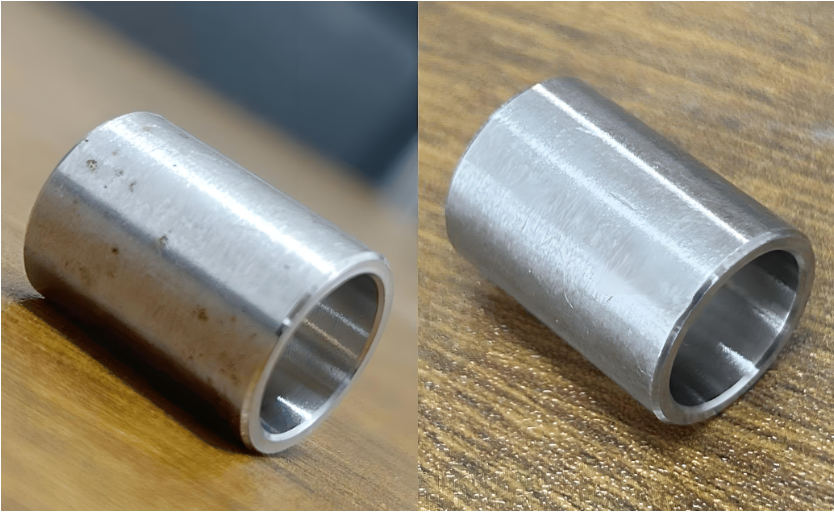

As-Machined

The “As-Machined” finish is the default and most cost-effective option. It is the raw surface left on the part directly after the final machining pass.

- What it is: No secondary finishing process is applied. The surface will have visible but subtle tool marks, often in a concentric or parallel pattern, known as the “machinist’s fingerprint.” The standard surface roughness is typically Ra 3.2 μm (125 μin).

- Best for: Prototypes, internal components, parts where function is the only priority, or when the tightest tolerances must be maintained without any surface alteration.

- Pros: Lowest cost, fastest turnaround, no impact on part dimensions.

- Cons: Visible tool marks, minimal corrosion protection.

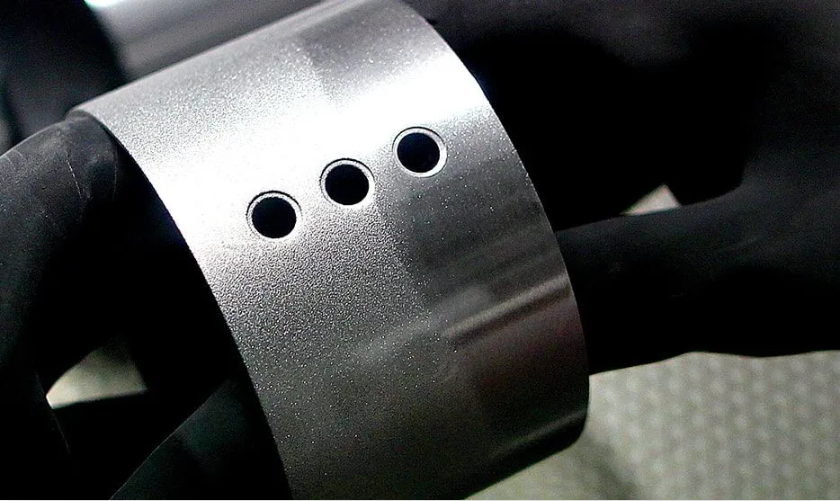

Bead Blasting

Bead blasting removes the tool marks and creates a uniform, non-reflective surface by propelling a stream of abrasive media (typically glass beads) against the part.

- What it is: A mechanical finishing process that results in a soft, matte, or satin texture. It is excellent for hiding fingerprints and minor surface imperfections.

- Best for: Creating a uniform visual appearance, reducing glare, and preparing a surface for anodizing or painting.

- Pros: Aesthetically pleasing matte finish, low cost, hides imperfections.

- Cons: Slightly reduces dimensional accuracy, offers minimal corrosion resistance on its own.

Anodizing (for Aluminum & Titanium)

Anodizing is an electrochemical process that grows a stable oxide layer on the surface of a metal, most commonly aluminum. This layer enhances durability and allows for dyeing.

- What it is: An electrically controlled oxidation process that creates a hard, corrosion-resistant, and electrically non-conductive ceramic layer.

- Best for: Aluminum parts requiring high durability, corrosion resistance, and cosmetic color.

- Pros: Excellent corrosion and wear resistance, can be dyed in a variety of colors, good paint primer.

- Cons: Only applicable to aluminum and titanium, can crack under high stress.

There are two common types:

- Type II Anodizing: The standard, cosmetic type. It offers good corrosion resistance and a wide range of color options.

- Type III Anodizing (Hardcoat): Creates a much thicker, denser, and harder layer, prioritizing wear resistance and durability over cosmetic appearance. Colors are typically limited to black or dark gray.

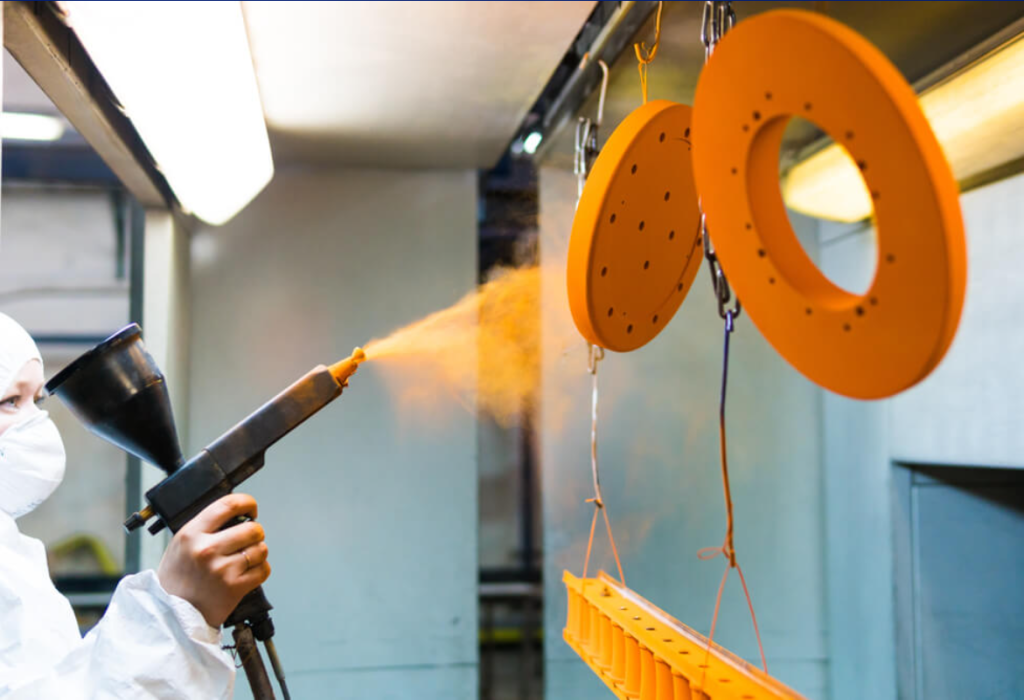

Powder Coating

Powder coating is a process where a dry, free-flowing powder is applied to a part electrostatically and then cured under heat. It creates a thick, durable, paint-like layer.

- What it is: A high-performance polymer finish that is tougher and more durable than conventional liquid paint.

- Best for: Steel, aluminum, and other metal parts that require high impact resistance and a durable colored finish (e.g., outdoor equipment, automotive brackets).

- Pros: Extremely durable and chip-resistant, wide range of colors and textures, excellent corrosion protection.

- Cons: Creates a thick layer (0.05 – 0.15 mm), which can interfere with tight tolerances.

Polishing

Polishing is a multi-step mechanical process of smoothing a surface using progressively finer abrasives to create a mirror-like, highly reflective finish.

- What it is: A labor-intensive process that smooths out microscopic imperfections to achieve high reflectivity.

- Best for: Cosmetic parts, optical components, and applications where a smooth, cleanable surface is required.

- Pros: Creates a visually striking mirror finish, very smooth surface.

- Cons: Labor-intensive and therefore expensive, removes a small amount of material, offers no protective benefits.

Passivation (for Stainless Steel)

Passivation is a chemical treatment for stainless steel that enhances its natural corrosion resistance.

- What it is: A process that removes free iron and other contaminants from the surface of stainless steel, allowing a robust, passive chromium-oxide layer to form. It does not change the appearance of the metal.

- Best for: All stainless steel parts, especially for medical and food-grade applications, to maximize corrosion resistance.

- Pros: Significantly improves corrosion resistance, cleans the part surface, no dimensional change.

- Cons: Only applicable to stainless steel.

How to Choose the Right Finish: A Quick Chart

| Primary Goal | Recommended Finish(es) | Common Materials | Relative Cost |

| Lowest Cost / Prototyping | As-Machined | All Metals | $ |

| Aesthetic Matte Finish | Bead Blasting | All Metals | $$ |

| Corrosion Resistance & Color | Anodizing (Type II) | Aluminum, Titanium | $$$ |

| Maximum Wear Resistance | Anodizing (Type III) | Aluminum, Titanium | $$$$ |

| Durable Color Finish | Powder Coating | Aluminum, Steel | $$$ |

| Mirror-Like Appearance | Polishing | All Metals | $$$$$ |

| Maximize Stainless Protection | Passivation | Stainless Steel | $$ |

Ready to Add the Perfect Finish to Your Parts?

Choosing the right surface finish is a critical final step in part manufacturing. The best choice always depends on a balance of your part’s function, desired appearance, and budget.

Our team has experience with a wide array of finishing processes. Upload your file, specify your requirements in the notes, and our experts will help you choose the best finishing options for your project.