Welcome to JFManufacturer

Your

Reliable Partner

Rapid Manufacturer

Solution Provide

For Custom

Prototyping/Production

We provide end-to-end manufacturing solutions for high-quality custom parts, from prototype to production. Our engineers support a wide range of materials and finishes to meet your specific project needs. Request your quote today.

- Metal & Plastic Machining

- CNC Milling

- CNC Turning

- Sheet Metal Fabrication

- Wire-Cut EDM & 3D Printing

Meticulously machined components delivered to your exact specifications for maximum reliability.

- Rigorous Quality Control

- Full Inspection Report

Fast, reliable turnaround times to keep your development and production schedules on track.

- High-Efficiency Machining

- Rapid Turnaround Times

Optimized processes and expert DfM feedback that reduce your costs, not quality.

- Competitive Prices

- Optimized Manufacturing Process

Your dedicated partner, focused on clear communication and your long-term success.

- Instant Quotation

- Long-Term Partnership Focus

Our manufacturing capabilities

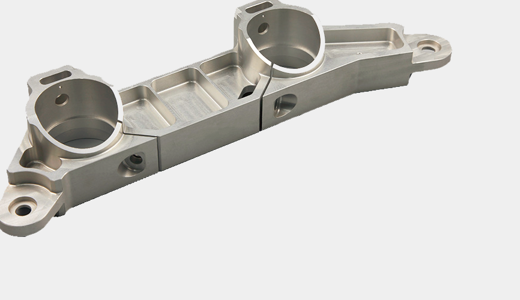

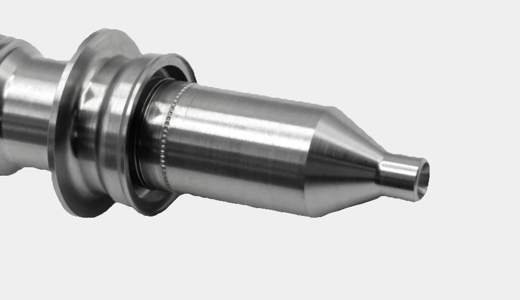

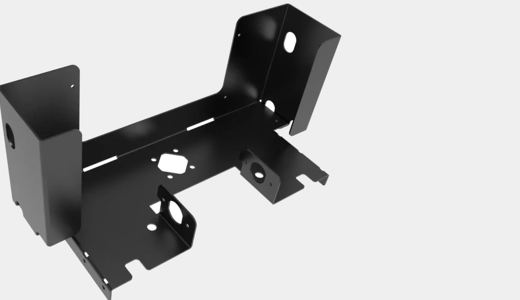

We are experts in converting complex engineering designs into mission-critical components. By integrating advanced CNC machining, precision sheet metal fabrication, and comprehensive finishing services, we provide a streamlined manufacturing solution from prototype to full-scale production.

5 Axis CNC Milling, 3+2Axis CNC Milling, 3 Axis CNC Milling

- Tolerances to 0.020mm

- Turnaround: From 5 days

3 Axis CNC Turning, Swiss Turning, CNC Turn-milling

- Tolerances to: ±0.010mm

- Volume: 1 to 1M pcs

Laser Cutting, Bending, Punching, Welding & Assembly

- Thickness from 0.2mm

- Volume: 1 to 1M pcs

DFM Analysis, Material Consulting, Finishing, Final Inspection & Logistics

- Expert DFM & Material Consulting

- Quality Assurance & Global Logistics

A Glimpse Into Our Workshop

Welcome to the heart of our operations. Our modern, well-organized facility is equipped with a comprehensive range of advanced machinery to handle your most complex manufacturing challenges. We invite you to take a virtual tour and see the environment where our commitment to quality, precision, and efficiency comes to life.

The Shenzhen Advantage

Our factory is strategically located in Shenzhen, China—the world’s epicenter for electronics manufacturing and high-tech innovation. This prime location gives us unparalleled access to a robust and efficient supply chain for raw materials, specialized tooling, and advanced finishing services. Being at the heart of this manufacturing ecosystem enables us to deliver high-quality, customized components with exceptional speed and cost-effectiveness.

Your Trusted Global Partner

Leveraging Shenzhen’s world-class logistics hub, we have become a trusted manufacturing partner for innovative companies across Europe, North America, and Australia. Our experienced team is proficient in navigating international shipping, customs, and communication, ensuring a seamless and reliable experience from quotation to delivery, no matter where you are.

- JFManufacturer Co., Ltd.

- Address:406 Dadongming Building, Guangming District, Shenzhen, China 518106

- Phone: +86 180 2874 8447

- Email: info@JFManufacturer.com

Who We Are

Your Trusted and Visionary Partner in Engineering Excellence

At JFManufacturer, we bridge the critical gap between design and production. Leveraging state-of-the-art CNC and sheet metal fabrication technology, we deliver uncompromising quality and reliability for your most demanding projects. We enable R&D manufacturers to innovate with confidence, knowing their components are machined to exact specifications, every time.

Our experts provide dedicated support.ensuring optimal desian efficiency andsuperior quality.

We pride ourselves on clear, proactive communication and dedicated project management, ensuring you are always in control of your project.

- Advanced Materials Machining

- From Prototype to Production

- Seamless Integration with Your R&D

Play intro

Our Vision

To be the most trusted manufacturing partner for the world’s leading innovators, empowering them to turn ambitious ideas into reality.

Our Mission

To consistently deliver high-precision components through superior engineering, meticulous process control, and a deep commitment to our clients’ success.

Our Motto

Precision in Everything: From engineering to execution, we pursue perfection. Reliable Partnership: We build success together through transparency and trust. Continuous Improvement: We embrace technology and innovation to always stay ahead.

Why Choose Us

Quality is Embedded in Our Process

Your Trusted Partner for High-Quality Manufacturing

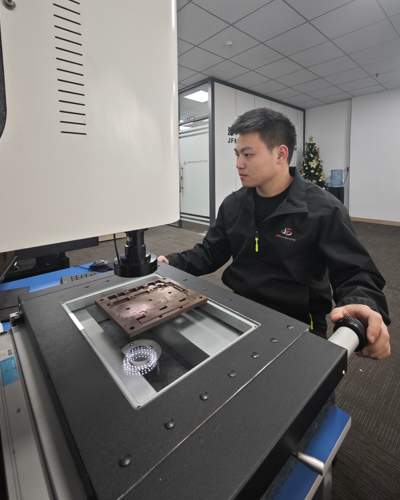

Our dedicated quality lab is equipped with advanced inspection tools, including CMM and optical measurement systems. We verify every critical dimension to ensure your parts strictly conform to the engineering drawings and specifications.

Our entire operation runs on an ISO 9001 certified quality management system. From raw material verification to in-process checks and final inspection, quality is rigorously controlled at every stage of production.

We provide comprehensive quality documentation for your peace of mind. This includes full material certifications and detailed inspection reports (e.g., CMM reports, First Article Inspection) with every shipment upon request.

Our quality is driven by a team of experienced engineers and technicians. We proactively provide Design for Manufacturability (DfM) feedback to help you optimize designs for better quality, reduced costs, and faster production.

What WE oFFER

Manufacturing Solutions for Demanding Industries

We partner with leaders across a diverse range of demanding industries, providing specialized manufacturing solutions tailored to their unique challenges and standards. Explore our expertise below to see how we can serve your specific sector.

Order & Payment

Most Popular Questions

We can typically hold tolerances of ±0.020mm (±0.001 in) for CNC machining. Tighter tolerances are possible upon review of the part geometry and material. Please specify all critical tolerances on your drawing.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

We work with a wide range of materials. For metals, we commonly machine Aluminum alloys, Stainless Steel, Brass, Copper, and Titanium. For plastics, we frequently use PEEK, Delrin (POM), Teflon, and Nylon. We can also source and machine other specialized materials upon request.

We offer comprehensive finishing services to provide production-ready parts. Our capabilities include Anodizing, Plating, Powder Coating, Bead Blasting, and Polishing. This allows us to be your one-stop shop from raw material to finished component.

Yes. We consider this a core part of our partnership approach. Our experienced engineers will review your designs and proactively provide suggestions to help optimize for better quality, reduced manufacturing costs, and faster production cycles, without compromising your design's intent.

Our machining capabilities can accommodate a wide range of part sizes. For our 3 and 5-axis CNC mills, the maximum travel is typically around X: 1200mm, Y: 600mm, Z: 600mm. For specific project requirements exceeding these dimensions, please contact us to discuss potential solutions.

We accept most standard CAD files, including STEP, IGES, SLDPRT, DWG, and DXF. For the most accurate quote, we recommend providing a 3D model along with a 2D drawing that specifies tolerances, materials, and required finishes.

Standard lead time for prototypes is typically 5-10 business days. Production lead times vary based on part complexity, quantity, and material availability, and will be specified in your formal quote. We also offer expedited services for urgent projects.

We do not have a strict MOQ. We support everything from single prototypes to full-scale production runs of thousands of parts.

To provide the most accurate quote, please include your 3D CAD files (e.g., STEP, IGS), 2D engineering drawings specifying all tolerances and finishes, the required quantity, material type, and any other critical project requirements.

Once you are ready to proceed, simply reply to the quote email to confirm your acceptance. We will then ask for an official Purchase Order (PO) to formally kick off the project.

For new clients, we typically require a deposit (e.g., 50%) upon order confirmation, with the balance due upon shipment. We accept bank transfers (T/T). For long-term partners with an established relationship, we can discuss more flexible payment terms.

Yes, we are a global supplier and ship worldwide. We work with trusted carriers like DHL, FedEx, and UPS to ensure reliable and timely delivery to our international clients.

We take great care in packaging. All parts are cleaned and inspected before being individually wrapped or placed in custom trays. We use protective materials like bubble wrap and custom foam inserts within sturdy cartons to ensure your components arrive in perfect condition.

Yes, we are flexible. While we have trusted logistics partners like DHL and FedEx, we can certainly work with your designated carrier and ship using your company's shipping account if you prefer.

Shipping times vary by destination and service level. For express air freight, shipments to most destinations in North America and Europe typically take 3-5 business days. We will provide a more accurate delivery estimate once your order is ready for dispatch.

Yes. Once your order has been dispatched, we will provide you with a shipping confirmation email that includes the carrier's name and a tracking number, allowing you to monitor the progress of your delivery online.

Our standard shipping term is EXW (Ex Works) or FOB (Free on Board) from our facility. This means the buyer is responsible for shipping costs and arrangements from that point. However, we can also arrange DDP (Delivered Duty Paid) shipping upon request, where we handle all shipping and customs clearance to your door.

Request a Quote

Ready to get started? Upload your CAD files and project details here. Our engineering team will review your request and provide a detailed quote, typically within 24 hours.

How We Work With You

We believe in a transparent and structured partnership. Our end-to-end process is designed to ensure clarity, mitigate risks, and deliver exceptional quality at every stage, from the initial NDA to the final delivery of your components.

Sign an NDA based on your projectreguirements to ensure strictadherence to its terms, protecting theconfidentiality of your information.

Evaluate project needs,identify critical elements, andaddress any specificrequirements.

We will provide fair andreasonable quotations, alongwith professionalsuggestions, valid for 30days.

Sign a quality agreement,business contract, or supplyagreement to mutuallyprotect the rights andinterests of both parties

Provide FAl sample confirmation andsealing, along with comprehensivedocumentation such as full-sizeinspection reports,surface treatmentreports, salt spray test reports, andmore.

Strictly adhere to SoP andSlP process controls toenhance productionefficiency and improve theyield rate in mass production.

We conduct a 100%inspection of all productsprior to shipment and providematerial reports along withCoC and packaginginformation.

Share your inspection resultsand satisfaction survey withus to help us continuouslyimprove our servicecapabilities