Our entire quality management system is certified to the ISO 9001:2015 standard. This certification is your assurance that we operate with a documented, systematic, and continuously improving process that is rigorously audited by a third party.

Our ISO 9001 system ensures that every project, from quotation to shipment, follows a clearly defined and repeatable procedure. This guarantees consistent results and reliable quality for every part, every time.

As a core requirement of our certification, we maintain meticulous records. This allows for full traceability of materials and processes, and enables us to provide comprehensive documentation (like CoC and inspection reports) for your projects.

To ensure every component strictly conforms to your requirements, our quality assurance process is built around three critical stages: verifying materials at the start, controlling the process throughout, and validating the final product before shipment.

All incoming raw materials are rigorously inspected and verified against material certifications (CoC) to ensure they meet the required specifications and standards before entering production.

We perform real-time dimensional and visual inspections at critical manufacturing stages. Our machinists and quality team follow strict Standard Operating Procedures (SOPs) to prevent deviations and ensure consistency.

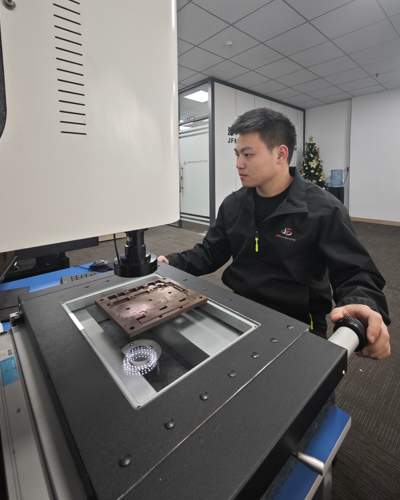

Every batch of finished components undergoes a comprehensive final inspection using our advanced metrology equipment. We verify all critical dimensions, features, and finishes against your engineering drawings to guarantee 100% compliance.

We invest in advanced metrology technology to guarantee the accuracy of your parts. Our dedicated, temperature-controlled quality lab is equipped with:

Coordinate Measuring Machine (CMM): For precise 3D measurement of complex geometries to sub-micron accuracy.

Optical Measurement Systems: For non-contact inspection of small or delicate features.

A full suite of calibrated inspection tools: Including digital micrometers, calipers, height gauges, and surface roughness testers.

This combination of advanced technology and skilled operators is your guarantee that every component we ship has been thoroughly verified and is ready for production.

We provide comprehensive documentation to ensure full traceability and compliance for your projects. Upon request, we can supply:

Material Certifications

Certificate of Conformance (CoC)

First Article Inspection (FAI) Reports

Full Dimensional Inspection Reports

Partner with a supplier who prioritizes quality as much as you do.

We believe in a transparent and structured partnership. Our end-to-end process is designed to ensure clarity, mitigate risks, and deliver exceptional quality at every stage, from the initial NDA to the final delivery of your components.

Sign an NDA based on your projectreguirements to ensure strictadherence to its terms, protecting theconfidentiality of your information.

Evaluate project needs,identify critical elements, andaddress any specificrequirements.

We will provide fair andreasonable quotations, alongwith professionalsuggestions, valid for 30days.

Sign a quality agreement,business contract, or supplyagreement to mutuallyprotect the rights andinterests of both parties

Provide FAl sample confirmation andsealing, along with comprehensivedocumentation such as full-sizeinspection reports,surface treatmentreports, salt spray test reports, andmore.

Strictly adhere to SoP andSlP process controls toenhance productionefficiency and improve theyield rate in mass production.

We conduct a 100%inspection of all productsprior to shipment and providematerial reports along withCoC and packaginginformation.

Share your inspection resultsand satisfaction survey withus to help us continuouslyimprove our servicecapabilities

Ready to get started? Upload your CAD files and project details here. Our engineering team will review your request and provide a detailed quote, typically within 24 hours.